Overview

Essential details

Place of Origin: Shandong, China

Product Type: FERTILIZER

Condition: New

Machine Type: Granulator

Video outgoing-inspection: Provided

Machinery Test Report: Provided

Marketing Type: New Product 2023

Warranty of core components: 1 Year

Core Components: PLC, Engine, Bearing, Gearbox, Motor, Gear

Voltage: Customized

Warranty: 1 year

Applicable Industries: Manufacturing Plant, Energy & Mining

Showroom Location: Egypt, Turkey, Saudi Arabia, Indonesia, India, Thailand, UAE, Algeria, South Africa, Nigeria, Uzbekistan

Application: Fertilizer Pellet Making Machine

Raw material: animal manure ,industry waste, agricultural waste etc

Capacity: 10000-300000T/Y

Final product: Ball Shape Fertilizer

Material: Carbon Steel Made

Working method: fermentation

Application Scope: NPK Fertilizer Industry ,organic fertilizer industry

Feature: High Working Efficiency

Pellet diameter: Fertilizer:2-6mm

After Warranty Service: Video technical support, Online support, Spare parts, Field maintenance and repair service

Local Service Location:

Egypt, Turkey, Viet Nam, Brazil, Saudi Arabia, Indonesia, Pakistan, India, Thailand, Kenya, UAE, Colombia, Algeria, Sri Lanka, South Africa, Ukraine

Certification: ISO900100:08

Product Overview

compost fertilizer production line

Compost is an organic fertilizer that uses various plant residues (crop straws, weeds, leaves, peat, garbage, and other wastes etc.) as the main raw materials, mixed with human and animal manure and decomposed by composting.

It is a kind of organic fertilizer, which contains rich nutrients, and has a long and stable fertilizer effect. At the same time, it promotes the formation of soil solid grain structure, can increase the soil's ability to retain water, heat, air, and fertilizer, and it can be mixed with chemical fertilizers. It can also make up for the shortcomings of the single nutrient contained in chemical fertilizers, and long-term single use of chemical fertilizers will harden the soil and reduce the performance of water and fertilizer retention.

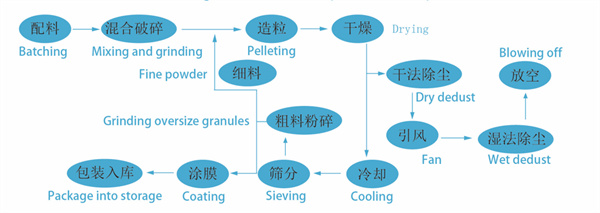

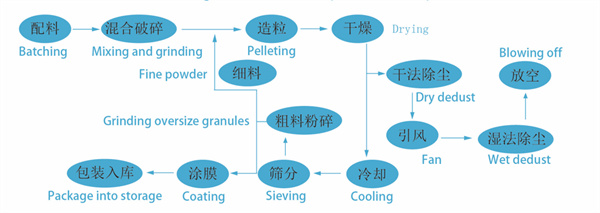

Production process of compost fertilizer production line

1. Fermentation:All kinds of compost raw materials will be put into the fermentation tank or by compost turner for fermentation;

2.Granulation:the raw materials will be fed into the granulator to make into fresh granules.

3.Drying:After granulation, though granules has been formed, but right now its moisture is too high, so they will be conveyed to the rotary dryer for drying.

4.Cooling:The temperature of the granules coming out of the dryer is quite high, then the granules will be send to the rotary cooler for cooling to further increase the granules strength and reduce the moisture.

5.Sieving:After cooling, the granules will be pass the sieve to separate coarse granules and fine powder, final product will be achieved. The big granules and the fine powder will go through the grinder and recycle to the granulator, which will make them participate in the granulation process again .

6. The granules after sieving will be sent to automatic packing machine and then storage in bulk.

Remark: This granulation process can be used for producing various kinds of fertilizer, includes organic fertilizer, NPK fertilizer, humic acid fertilizer and controlled release fertilizer etc, it can be used for hundreds of formulas of fertilizer.This production line is a multi-function production line.

Related machines of compost fertilizer production line

Compost turner

The compost turner is used for fermenting the organic raw materials.

Belt conveyor

Belt conveyor is mainly used to transport particles and powder materials in fertilizer, grain and other field.

It is a kind of transportation machine which is high capacity, low energy consumption, long service life, low noise, easy installation and maintenance, wide usage and other characters.

Rotary granulator, disc granulator or compact granulator

The granulator is used for making the raw materials into granules ,we also have disc granulator ,double roller compact granulator for your option.

Rotary dryer

The rotary dryer is used for drying the organic fertilizer granules.

Rotary cooler

The rotary cooler is used for cooling the organic fertilizer granules,in addition ,it can increase the strength of the granules.

Rotary sieve

The rotary sieve is used for seperating the qualified granules and oversize materials,we also have vibrating sieve for your option.

Packing machine

DCS-50 packing machine is an electrical automatic packaging scale. It uses three-phase 380V AC power supply, peak current control mode; air consumption is 0.4-0.8Mpa. It can be widely used in building, chemicals, food, steel, feed and other industries.

SALES AND SERVICE NETWORK

Successful Project

Delivery machines to our clients

FAQ

1. Are you a manufacturer factory?

A: Yes, we are the professional manufacturer of the fertilizer machines for 30 years.

2. Could you provide the installation, commssioning, training or other kinds service?

A: Yes, we could arrange professional engineers to install the machines ,train your workers and test run the complete production line until your workers handle the operation; in addition ,we can supply the fertilizer fomulars for free.

3.Do you have customers near your factory, then can we visit the running fertilizer machines line?

A:Yes, there are many clients near our factory, we could take you to check the running fertilizer machines line.

4.Do you have experience in exporting, installing and training the NPK fertilizer machines line in Africa, Southeast Asia, Middle East, South Asia, central Asia, Central America?

A:Yes, we have rich experience. Our fertilizer machines had exported to Saudi Arabia, India, Indonesia, South Africa, Nigeria, Dominica, Kazakhstan, Spain, Vietnam and other countries.

Related products:

1.Organic fertilizer production line

2.NPK compound fertilizer production line

3.Rotary drum granulator