Essential details

Place of Origin: China

Product Type: FERTILIZER

Condition: New

Machine Type: Granulator

Video outgoing-inspection: Provided

Machinery Test Report: Provided

Marketing Type: New Product 2023

Warranty of core components: 1 Year

Core Components: PLC, Engine, Bearing, Gearbox, Motor, Gear

Voltage: customized

Warranty: 1 year

Applicable Industries: Manufacturing Plant, Energy & Mining, Other

Showroom Location:

Egypt, Turkey, Viet Nam, Saudi Arabia, Indonesia, Pakistan, India, Thailand, UAE, Algeria, South Africa, Nigeria, Uzbekistan

Application: Fertilizer granules Making Machine

Capacity: 1-30t/h

Final product: Ball Shape Fertilizer

Material: Carbon Steel Made

Application Scope: NPK Fertilizer Industry ,organic fertilizer industry

Feature: High Working Efficiency

After Warranty Service: Field maintenance and repair service

Granulate size: Adjustable

Working method: Agglomerate

Packaging & delivery : standard container

Port: Qingdao ,Shanghai, Tianjin

Lead time:

|

Quantity(sets)

|

1 - 10

|

>10

|

|

Lead time (days)

|

20

|

To be negotiated

|

Introduction:

Rotary drum granulator is a critical machine in fertilizer production process.Its quality decides directly the efficiency and quality of end product.Pellets produced via granulator machine are a little more dense,and more sepherical than other agglomeration methods.

1 How rotary drum granulator works?

Its main work method is reunited wet granulation, with the founction of a certain amount of water or steam, the powder or fine type raw materials feed into the drum reunion into pellets with the rotation of cylinder.

2 The component of rotary drum granulator

1 Raw material feed chute

2 Riding ring

3 Ring gear and ring gear guard

4 Drive assembly

5 Lining

6 Discharge part

7 Exhaust discharge system

Outside view

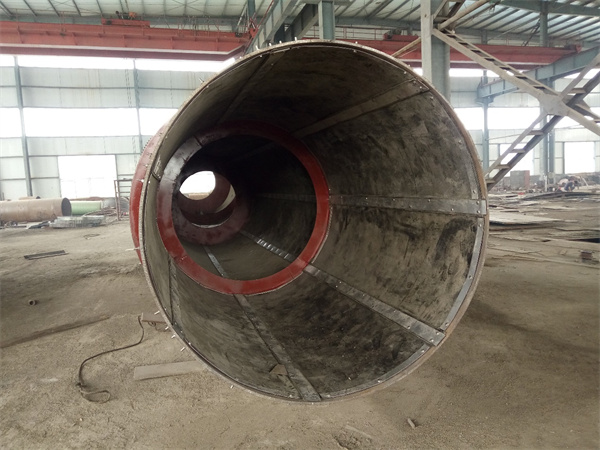

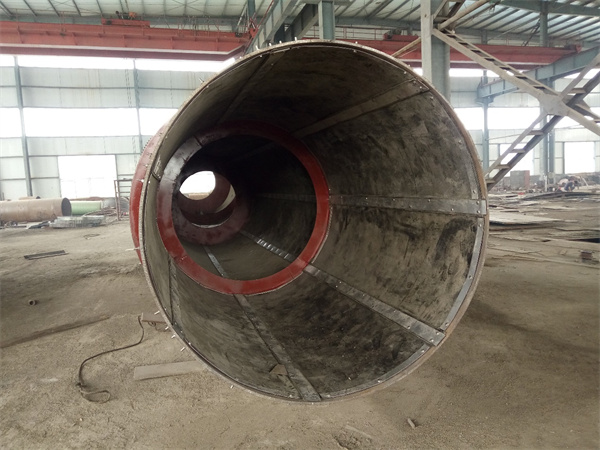

Inner structure

Features:

1.It is used for producing high,medium,low concentration of compound fertilizers,organic fertilizer and other kinds of fertilizer,it can also be used for other field,such as agricultural, mining and chemical industry for various products.

2 The inner wall of the granulator uses a special customized rubber lining,it has the advantage of anti-corrosion,effectively

prevent high temperature and anti-rusty.

3. The granulation rate is high, the end product is good-quality with more dense with perfect surface.

Product specifications:

|

Model

|

Size

|

Capacity(t/h)

|

Inclination (degree)

|

Rotate speed (rpm)

|

Motor power(kw)

|

|

ZL1405

|

φ1.4mX5m

|

3-4

|

2-2.5

|

13.5

|

11

|

|

ZL1606

|

φ1.6mX6m

|

5-8

|

2-2.5

|

12

|

15

|

|

ZL1806

|

φ1.8mX6m

|

8-10

|

2-2.5

|

11.5

|

18.5

|

|

ZL2008

|

φ2.0mX8m

|

10-15

|

2-2.5

|

10.2

|

22

|

|

ZL2208

|

φ2.2mX8m

|

16-20

|

2-2.5

|

9.7

|

30

|

|

ZL2408

|

φ2.4mX8m

|

20-22

|

2-2.5

|

9.7

|

45

|

|

ZL2610

|

φ2.6mX10m

|

22-30

|

2-2.5

|

9.2

|

55

|

Final products shows

Delivery site

Successful projects

FAQ

1. Are you a manufacturer factory?

A: Yes, we are the professional manufacturer of the fertilizer machines for 30 years.

2. Could you provide the installation, commissioning, training or other kinds service?

A: Yes, we could arrange professional engineers to install the machines ,train your workers and test run the complete production

line until your workers handle the operation; in addition ,we can supply the fertilizer fomulars for free.

3.Do you have customers near your factory, then can we visit the running fertilizer machines line?

A:Yes, there are many clients near our factory, we could take you to check the running fertilizer machines line.

4.Do you have experience in exporting, installing and training the NPK fertilizer machines line in Africa, Southeast Asia, Middle East, South Asia, central Asia, Central America?

A:Yes, we have rich experience. Our fertilizer machines had exported to Saudi Arabia, India, Indonesia, South Africa, Nigeria, Dominica, Kazakhstan, Spain, Vietnam, Nigeria ,Kenya ,South Africa, Ethiopia and other countries.

Related products:

1.NPK fertilizer production line

2.Organic fertilizer production line

3.Rotary dryer