Essential details

Type: Rotary Drying Equipment

Application: Chemicals Processing, Chemical Industry

Condition: New

Place of Origin: China

Key Selling Points: Automatic

Warranty:1 Year

Applicable Industries: Manufacturing Plant, Farms, Energy & Mining

Showroom Location: Egypt, Turkey, Viet Nam, Saudi Arabia, Indonesia, India, Thailand, Nigeria, Kenya ,Ethiopia, Uzbekistan

Marketing Type: New Product 2023

Machinery Test Report: Provided

Video outgoing-inspection: Provided

Warranty of core components: 1 Year

Core Components: Bearing

Material: Other, State Standard Carbon Steel

Usage: Drying materials

Function: High Efficiency

Capacity: 10000-300000T/Y

Working method: Dry materials

Installation: professional team

Advantage: Low Consumption and High Efficiency

After-sales Service Provided: Field installation, commissioning and training

Supply Ability: 20 Set/Sets per Month

Packaging & delivery

Packaging Details: Standard container

Loading Port: Qingdao ,Tianjin ,Shanghai

Lead time:

|

Quantity(sets)

|

1 - 10

|

>10

|

|

Lead time (days)

|

30

|

To be negotiated

|

Product Overview

Rotary dryer-fertilizer dryer machine is an important machine in fertilizer production line. It can dry not only NPK fertilizer but also organic fertilizer and many other kinds of fertilizers. In addition, it can be widely used for mining industry, sand drying, coal drying, pharmaceutical industry and many other industries.

1.The Components of Rotary Dryers

1.1 Shell: The shell of rotary dryer can be made from a variety of materials, including carbon steel, stainless steel and a variety of alloys.

1.2 Raw material feed: The raw material feed area, also called the feed chute, is where feedstock is fed into the system, typically by a feed screw or chute.

1.3 Drive assembly: The drive assembly is the mechanism that cause the drum to rotate. Several options are available here, but the gear and pinion are the best choice.

1.4 Riding ring: Riding ring add structural support for the drum, and serve as a place to burden the pressure of the whole shell.

1.5 Thrust rollers: Thrust rollers push on the riding ring to stop the drum from drifting, or moving horizontally.

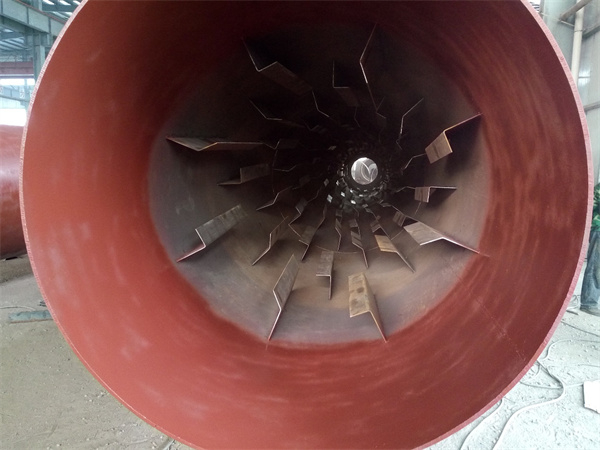

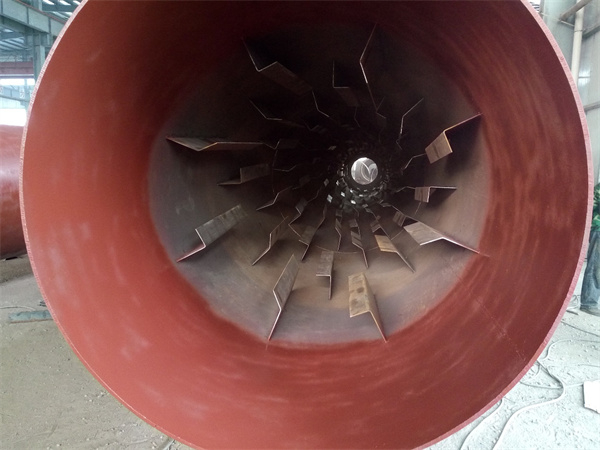

1.6 Flights: Available in several designs, material lifter, or flights, help to maximize efficiency of heat transfer between the material and the drying air.

1.7 Product discharge: The product discharge area is where product exits the dryer. Here, product can move on to the next step in the process flow.

1.8 Knocking systems: Knocking systems help to prevent build-up within the dryer, by knocking off material as the drum rotates.

2.How Rotary Dryers Work

Rotary dryers are comprised of a rotating drum,into which the material is fed,in combination with the drying air.Flights,or lifters,pick up the material from the bed,carrying it over,and dropping it through the air stream as the drum rotates to maximize heat transfer between the material and drying air.The tumbling action given by a drum offers the added benefit of polishing the pellets,further rounding them as they dry.

3. FEATURES AT A GLANCE

1.The shell of the rotary dryer uses assembled structure, it is easy to transport

2 Add granulation area,improves the granulation effect,increase the surface finish and strength of particle

3 The banking plank adopts modular structure,for the materials bestrew the entire interface of shell,so that heat exchange is

thorough.

4 Set with thermometer,vibration device,sealing devices,improves production efficiency.

outside view

inner structure

Driving system

4.PRODUCT SPECIFICATIONS

|

Model

|

Size

|

Capacity

(t/h)

|

Inclination

(degree)

|

Inlet

temperature

(℃)

|

Discharge moisture (%)

|

Power (kw)

|

|

HG1212

|

Φ1.2*12

|

1-2

|

2-3

|

110-300

|

1-4

|

11

|

|

HG1515

|

Φ1.5*15

|

3-4

|

2-3

|

110-300

|

1-4

|

15

|

|

HG1818

|

Φ1.8*18

|

5-7

|

2-3

|

110-300

|

1-4

|

22

|

|

HG2020

|

2.0*20

|

8-10

|

2-3

|

110-300

|

1-4

|

30

|

|

HG2222

|

Φ2.2*22

|

10-14

|

2-3

|

110-300

|

1-4

|

37

|

|

HG2424

|

Φ2.4*24

|

14-16

|

2-3

|

110-300

|

1-4

|

55

|

|

HG2626

|

Φ2.6*26

|

16-18

|

2-3

|

110-300

|

1-4

|

75

|

|

HG2828

|

Φ2.8*28

|

18-20

|

2-3

|

110-300

|

1-4

|

90

|

|

HG3030

|

Φ3.0*30

|

20-30

|

2-3

|

110-300

|

1-4

|

132

|

|

HG3232

|

Φ3.2*32

|

30-35

|

2-3

|

110-300

|

1-4

|

150

|

5.SALES AND SERVICE NETWORK

6.Successful Projects

Project in Indonesia

Project in Vietnam

Project in Saudi Arabia

Delivery site

FAQ

1. Are you a manufacturer factory?

A: Yes, we are the professional manufacturer of the fertilizer machines for 30 years.

2. Could you provide the installation, commissioning, training or other kinds service?

A: Yes, we could arrange professional engineers to install the machines ,train your workers and test run the complete production

line until your workers handle the operation; in addition ,we can supply the fertilizer fomulars for free.

3.Do you have customers near your factory, then can we visit the running fertilizer machines line?

A:Yes, there are many clients near our factory, we could take you to check the running fertilizer machines line.

4.Do you have experience in exporting, installing and training the NPK fertilizer machines line in Africa, Southeast Asia, Middle East, South Asia, central Asia, Central America?

A:Yes, we have rich experience. Our fertilizer machines had exported to Saudi Arabia, India, Indonesia, South Africa, Nigeria, Dominica, Kazakhstan, Spain, Vietnam, Nigeria ,Kenya ,South Africa, Ethiopia and other countries.

Related products:

1.NPK fertilizer production line

2. Organic fertilizer production line

3.Rotary drum granulator