Essential details

Place of Origin: China

Product Type: FERTILIZER

Condition: New

Machine Type: Granulator

Video outgoing-inspection: Provided

Machinery Test Report: Provided

Marketing Type: New Product 2023

Warranty of core components: 1 Year

Core Components: PLC, Engine, Bearing, Gearbox, Motor, Gear

Brand Name: Reascend

Voltage: Customized

Dimension(L*W*H): Depends on capacity

Warranty: 1 Year

Key Selling Points: High Productivity

Applicable Industries: Manufacturing Plant, Farms, Energy & Mining, Other

Showroom Location: Viet Nam, Indonesia, India, Thailand, South Korea, UAE, South Africa, Nigeria, Uzbekistan, Malaysia

Application: Fertilizer Pellet Making Machine

Usage: Producing NPK Compound Fertilizer Granules

Raw material: Urea, Ammonium Sulfate, MAP, DAP etc

Capacity: 10000-300000T/Y

Material: State Standard Carbon Steel

Final product: Granules

Working method: Agglomerate

Installation: Professional installation team

After-sales Service Provided: Field maintenance and repair service

Product Description

1.What's the raw materials can be used to produce NPK fertilizer ?

1.1 As the source of nitrogen,urea,ammonium hydrogen carbonate,ammonium chloride,ammonium sulfate,ammonium nitrate and other materials which are rich in nitrogen are the best choice

1.2 As the source of phosphorus,superphosphate,triple superphosphate,mono-ammonium phosphate,diammonium phoaphate are the best choice.

1.3 Potassium sulfate,potassium chloride can be selected as the ideal source of potassium.

1.4 Some fertilizer maybe require micro nitrient ,various options such as Bo,Zn,Mn can be done,it all depends on the soil testing and fertilizer fomular.

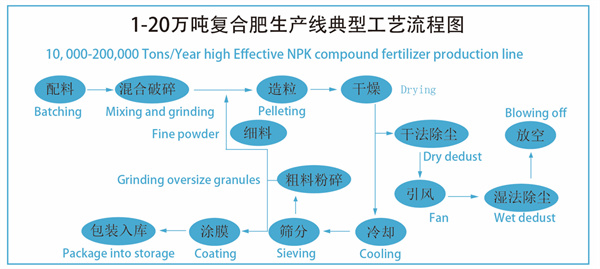

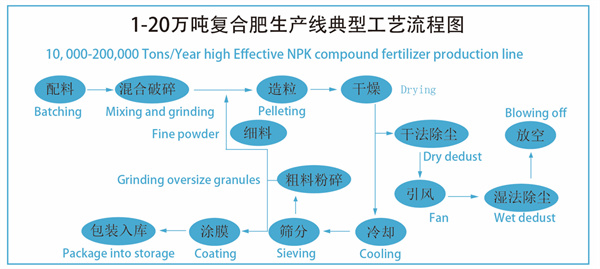

2.Production process of NPK compound fertilizer

1.Batching :All kinds of raw materials will be fed into the electronic belt scale by which will measure the weight and ratio of each raw material exactly .It is controlled by automatic computer.

2.Graulation:the raw materials will be fed into the granulator to make into fresh granules.

3.Drying:After granulation, though granules has been formed, but right now its moisture is too high, so they will be conveyed to the rotary dryer for drying.

4.Cooling:The temperature of the granules coming out of the dryer is quite high, then the granules will be send to the rotary cooler for cooling to further increase the granules strength and reduce the moisture.

5.Sieving:After cooling, the granules will be pass the sieve to separate coarse granules and fine powder, final product will be achieved. The big granules and the fine powder will go through the grinder and recycle to the granulator, which will make them participate in the granulation process again .

6. Coating :The granules after sieving will be sent into coating machine to spray a film on the granules surface ,which can protect the granules with the air .

7.Packing :After coating ,the granules will be delivered to automatic packing machine and then storage in bulk.

Remark: This granulation process can be used for producing various kinds of fertilizer, includes NPK fertilizer, organic fertilizer, humic acid fertilizer and controlled release fertilizer etc, it can be used for hundreds of formulas of fertilizer .This production line is a multi-function production line.

3.Traits of NPK compound fertilizer making equipments

A.The source of raw feedstock are wide and various,the production fomular are easy to operate.It can be used to produce high,medium and low concentration of compound fertilizer.

B.The investment cost is low but the production are effective and achieve high yield .The whole process is very convenient to operate and maintain

C.The production technology is mature and various solution can be offered to our customers.

project show

Our fertilizer equipments have exported to South Africa,India,Korea,India,Saudi Arabia,Indonesia, Malaysia, Loas, Vietnam,Dominician republic,Mongolia,Spain and other countries.

Delivery site of NPK fertilizer making equipments to Indonesia client

The installation site of NPK compound fertilizer making equipments

The installation site of annual capacity 30,000 tons NPK fertilizer project in Vietnam

Loading equipments to our clients

Our fertilizer projects in China and other countries

NPK and organic fertilizer project in Africa

FAQ

1. Are you a manufacturer factory?

A: Yes, we are the professional manufacturer of the fertilizer machines for 30 years.

2. Could you provide the installation, commissioning, training or other kinds service?

A: Yes, we could arrange professional engineers to install the machines ,train your workers and test run the complete production

line until your workers handle the operation; in addition ,we can supply the fertilizer fomulars for free.

3.Do you have customers near your factory, then can we visit the running fertilizer machines line?

A:Yes, there are many clients near our factory, we could take you to check the running fertilizer machines line.

4.Do you have experience in exporting, installing and training the NPK fertilizer machines line in Africa, Southeast Asia, Middle East, South Asia, central Asia, Central America?

A:Yes, we have rich experience. Our fertilizer machines had exported to Saudi Arabia, India, Indonesia, South Africa, Nigeria, Dominica, Kazakhstan, Spain, Vietnam, Nigeria ,Kenya ,South Africa, Ethiopia and other countries.

Related products:

1.Organic fertilizer production line

2.Rotary dryer

3.Rotary drum granulator