Overview

Essential details

Place of Origin: Shandong, China

Product Type: Fertilizer

Condition: New

Machine Type: Granulator

Video outgoing-inspection: Provided

Machinery Test Report: Provided

Marketing Type: New Product 2023

Warranty of core components: 1 Year

Core Components: Engine, Gearbox, PLC, Bearing, Gear

Voltage: Customized

Dimension(L*W*H): Customized

Warranty: 1 Year

Applicable Industries: Farms, Manufacturing Plant, Energy & Mining, Other

Showroom Location: Turkey, Bangladesh, Nigeria, Kenya, Thailand, Viet Nam

Application: Fertilizer Pellet Making Machine

Raw material: Organic Material, animal manure, household garbage, chicken waste and etc

Capacity: 1-30 t/h

Type: Automatic Line

Material: Carbon steel or stainless steel

Production process: Fermantation

Particle size: 1-6mm

Driving method: Mechanical drive

After-sales Service Provided: Field installation, commissioning and training

Product Description

The organic fertilizer equipments are developed to solve the existing problems faced by the global population,it includes the increasing amount of waste,severe soil pollution,soil runoff,inorganic fertilizer damage to the soil and other problems. It is critical to convert the organic materials into helpful and rich-in -nutrient fertilizer.

1.What can be used as the raw materials of organic fertilizer?

1.1 Agricultural waste: such as straw, soybean meal, cottonseed meal and so on.

1.2 Animal manure: such as chicken manure, cattle and sheep horse manure, rabbit manure; This is also the major source of the organic material.

1.3 Industrial waste: such as mash, vinegar residue, cassava residue, sugar residue, furfural residue;

1.4 Household garbage : such as kitchen waste

1.5 Urban sludge: such as river silt, sewage sludge.

2.How to deal with the organic materials?

Human and animal manure, garbage and other organic waste is a kind of dirty, rotten, smelly substances, which contains many pathogenic microorganisms, or mixed with certain toxicants, is an important source of pollution. Due to the problem of additives in the process of livestock breeding, there is sometimes a problem of heavy metals in livestock manure. As the source of raw materials varied, organic fertilizer, if not fully decomposed or disinfected in dealing with, it will bring a lot of pests and diseases.So before the organic materials are put into the production,they have to be screened and fermentated thoroughly.

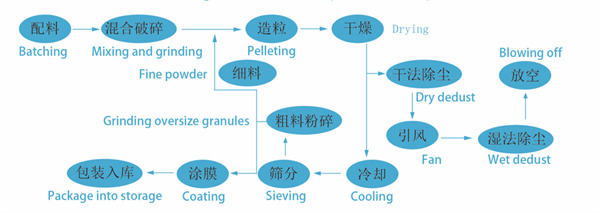

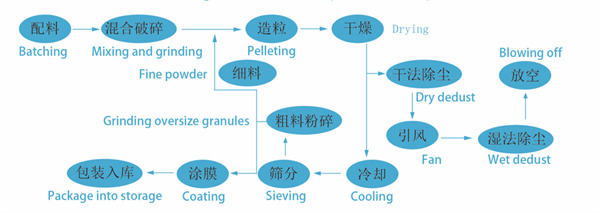

3.The components of organic fertilizer production line

3.1 Pre-conditioning system,it includes the following steps:

3.1.1 Drying:if the moisture content of the raw materials is too high,the pre-drying will be necessary.

3.1.2 Grinding:Grinding will be necessary if the material contains large particles which will prevent the granulation efficiency,

3.1.3 Composting or fermentation:this step can effectively kill the harmful pathogen and bacteria and decrease the moisture content and make the wet materials drier.

3.2 Electronic belt scale,all materials will be batching automatically.

3.3 Mixing machine or grinding machine,various options based on process requirements

3.4 Belt conveyor and bucket elevator

3.5 Rotary granulator or disc granulator,various options base on process requirements

3.6 Rotary dryer machine

3.7 Rotary cooler machine

3.8 Rotary sieve or vibrating screen

3.9 Coating machine

3.10 Packing machine and stack

Remark: This granulation process can be used for producing various kinds of fertilizer, includes organic fertilizer, NPK fertilizer, humic acid fertilizer and controlled release fertilizer etc, it can be used for hundreds of formulas of fertilizer. This production line is a multi-function production line.

SALES AND SERVICE NETWORK

Successful Project

Delivery machines to our clients

FAQ

1. Are you a manufacturer factory?

A: Yes, we are the professional manufacturer of the fertilizer machines for 30 years.

2. Could you provide the installation, commssioning, training or other kinds service?

A: Yes, we could arrange professional engineers to install the machines ,train your workers and test run the complete production line until your workers handle the operation; in addition ,we can supply the fertilizer fomulars for free.

3.Do you have customers near your factory, then can we visit the running fertilizer machines line?

A:Yes, there are many clients near our factory, we could take you to check the running fertilizer machines line.

4.Do you have experience in exporting, installing and training the NPK fertilizer machines line in Africa, Southeast Asia, Middle East, South Asia, central Asia, Central America?

A:Yes, we have rich experience. Our fertilizer machines had exported to Saudi Arabia, India, Indonesia, South Africa, Nigeria, Dominica, Kazakhstan, Spain, Vietnam and other countries.

Related products:

1.Compost fertilizer production line

2.NPK compound fertilizer production line

3.Rotary dryer