Overview

Essential details

Place of Origin: Shandong, China

Product Type: FERTILIZER

Condition: New

Machine Type: Granulator

Video outgoing-inspection: Provided

Machinery Test Report: Provided

Marketing Type: New Product 2023

Warranty of core components: 1 Year

Core Components: PLC, Engine, Bearing, Gearbox, Motor, Gear

Voltage: Customized

Warranty: 1 year

Applicable Industries: Manufacturing Plant, Energy & Mining, Other

Showroom Location: Egypt, Turkey, Saudi Arabia, Indonesia, India, Thailand, UAE, Algeria, South Africa, Nigeria, Uzbekistan

Application: Fertilizer Pellet Making Machine

Raw material: Chemical Powder, organic waste

Capacity: 10000-300000T/Y

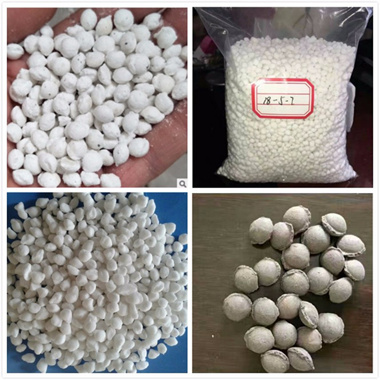

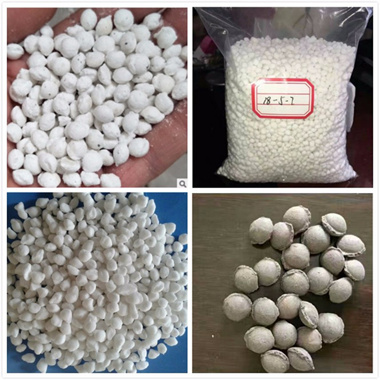

Final product: Ball Shape Fertilizer

Material: Carbon Steel Made

Working method: Double roller Compact

Application Scope: NPK Fertilizer Industry ,organic fertilizer industry

Feature: High Working Efficiency

Pellet diameter: Fertilizer:3-5mm

After Warranty Service: Field maintenance and repair service

Port: Qingdao ,Shanghai, Tianjin

Product Overview

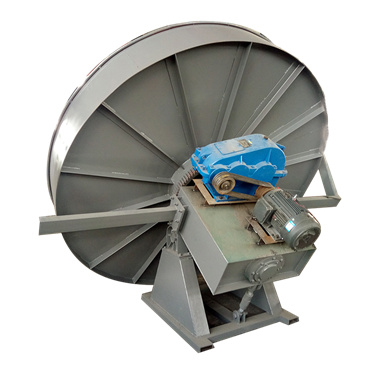

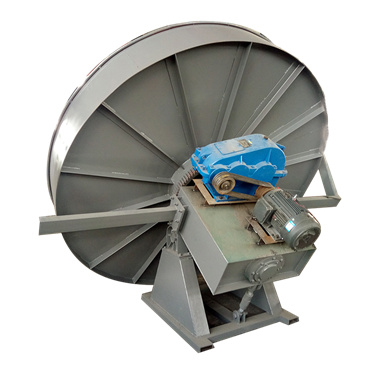

Compact granulator- double roller granulator

The compact granulator is a dry granulation process that uses pressure to agglomerate solid materials. This is achieved by squeezing the material bytwo counter-rotating rollers, which are driven by an eccentric sleeve or hydraulic system. When the solid material is squeezed, the air between the powder particles is first removed to rearrange the particles to eliminate the gaps between the materials.

1. How compact granulator works?

The dry powder material is added from the top of the extruder, and under the action of the rotating extrusion pressure of the two press rollers, the material produces plastic deformation and is compressed into sheets. In the process of crushing, granulation and screening, the flake materials can get granular products. By changing the groove form of the roll surface, the material of sheet, strip and flat ball can be obtained. The extrusion pressure of the extrusion granulator can be controlled according to the adjustment.

2.Application scope

1) Granulation of bio-organic fertilizer using grass charcoal, lignite, organic fertilizer sludge, and straw as raw materials;

2) Granulation of NPK compound fertilizer;

3) Granulation of cake fertilizer with bean cake as the main raw material;

4) Pelleting of complete feed and mixed feed using corn, beans and grass meal as raw materials;

5) Pelletization of biological feed straw pellets with crop straws as raw materials.

FEATURES AT A GLANCE

1.The compact granulator works at room temperature and does not need to process the raw materials too much; 2. It is easy to use, simple to operate, low investment, quick to pay back, and good economic benefits; 3. The compact granulator consumes less power when running, it is stable, saveing energy and electricity. 4. It has reasonable design, low maintenance cost, easy maintenance and replacement of accessories; 5. It has a wide application range, and the granule strength can be adjusted freely according to different materials; 6. It can control environmental pollution, reduce powder waste and packaging costs, and improve product transportation capabilities.

PRODUCT SPECIFICATIONS

|

Model

|

Size

|

Capacity (t/h)

|

Roller diameter (mm)

|

Roller length (mm)

|

Motor power (kw)

|

|

GY300

|

1400mm×700mm×1600mm

|

1.2-2.0

|

Ø155mm

|

290mm

|

22

|

|

GY145-220F

|

1500mm×750mm×1300mm

|

1.0-1.5

|

Ø145mm

|

220mm

|

15

|

Final granules produced by our machines

SALES AND SERVICE NETWORK

Successful Project

Project in China

Project in Indonesia

Project in Saudi Arabia

Delivery machines to our clients

Related products:

1.Rotary drum granulator

2.Disc granulator

3.Rotary dryer