Overview

Essential details

Place of Origin: Shandong, China

Product Type: FERTILIZER

Condition: New

Machine Type: Granulator

Video outgoing-inspection: Provided

Machinery Test Report: Provided

Marketing Type: New Product 2023

Warranty of core components: 1 Year

Core Components: PLC, Engine, Bearing, Gearbox, Motor, Gear

Voltage: Customized

Warranty: 1 year

Applicable Industries: Manufacturing Plant, Energy & Mining

Showroom Location: Egypt, Turkey, Saudi Arabia, Indonesia, India, Thailand, UAE, Algeria, South Africa, Nigeria, Uzbekistan

Application: Fertilizer Pellet Making Machine

Raw material: urea ,MAP,DAP,SSP,TSP ,etc

Capacity: 10000-300000T/Y

Final product: Ball Shape Fertilizer

Material: Carbon Steel or Stainless steel

Working method: Blending

Application Scope: NPK Fertilizer Industry ,organic fertilizer industry

Feature: High Working Efficiency

Pellet diameter: Fertilizer:3-5mm

After Warranty Service: Video technical support, Online support, Spare parts, Field maintenance and repair service

Local Service Location:

Egypt, Turkey, Viet Nam, Brazil, Saudi Arabia, Indonesia, Pakistan, India, Thailand, Kenya, UAE, Colombia, Algeria, Sri Lanka, South Africa, Ukraine

Certification: ISO9001

Product Overview

NPK bulk blending fertilizer , also known as BB fertilizer, is a fertilizer containing any two or three of the three nutrient elements of nitrogen, phosphorus, and potassium. It is made from single fertilizer or compound

fertilizer through simple mechanical mixing. There is no significant chemical reaction during the mixing process.

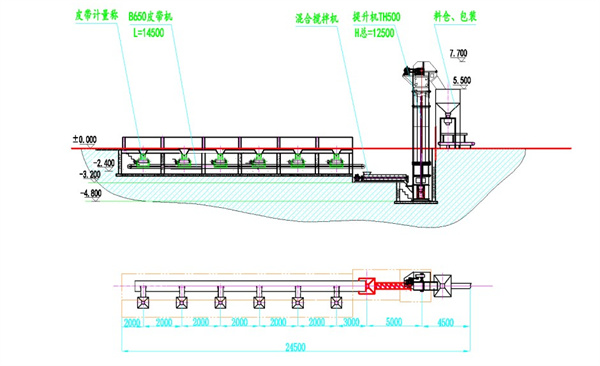

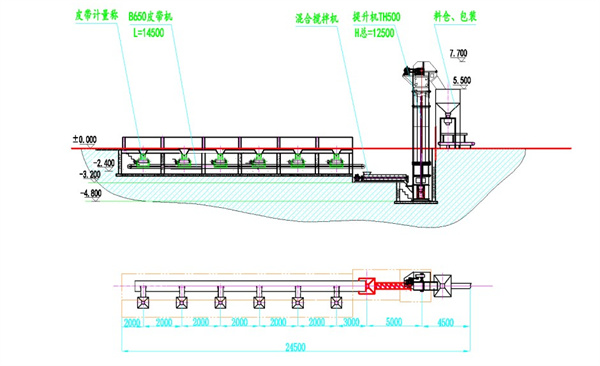

Production process of NPK bulk blending fertilizer production line

.

.

1. Fully automatic batching system

All raw materials are fed into the feeding port, and the batching of several raw materials is automatically completed according to the weight ratio preset by the electronic belt scale.

2. Raw material mixing

After the proportioning, the raw materials fall on the belt conveyor and are transported to the mixer through it, so that the

various materials are fully mixed and evenly mixed.

3. Quantitative packaging machine:

The evenly mixed materials are transported to the silo by the elevator (or belt conveyor), and the finished products are packaged by the quantitative packaging machine, and finally put into storage for sale.

Related machines of NPK bulk blending fertilizer production line

Electronic belt scale- batching system

Electronic belt scale refers to an automatic weighing instrument that continuously weighs the bulk materials on the conveyor belt without subdividing the quality or interrupting the movement of the conveyor belt. Various raw materials is automatically completed according to the weight ratio preset by the electronic belt scale.

Belt conveyor

Belt conveyor is mainly used to transport particles and powder materials in fertilizer, grain and other field.

It is a kind of transportation machine which is high capacity, low energy consumption, long service life, low noise, easy installation and maintenance, wide usage and other characters.

Horizontal mixer

This machine is a horizontal medium-sized transport and stirring equipment, through rotating for the purpose of stirring and transport the material. Taking into account the materials adhesion character in the production process, the stirring wheels is made of special blade, so that the material is not easy to adhere to the roots and reduce the difficulty to clean up.

The machine has the characters of running smoothly, easy to use, large capacity, simple maintenance and can be used for powder

materials stirring and conveying.

Bucket elevator

Bucket elevator is used for vertical lifting of loose materials or small pieces of material straight .

The machine adopts rapidly centrifugal discharge materials, to use the chain as the traction parts, to enhance the stability of

materials, small footprint, good sealing, easy management, long life, safe and reliable.

Packing machine

DCS-50 packing machine is an electrical automatic packaging scale. It uses three-phase 380V AC power supply, peak current control mode; air consumption is 0.4-0.8Mpa. It can be widely used in building, chemicals, food, steel, feed and other industries.

SALES AND SERVICE NETWORK

.

.

Related products:

1.NPK compound fertilizer production line

2.Rotary drum granulator

3.Rotary dryer