Overview

Essential details

Place of Origin: China

Product Type: FERTILIZER

Condition: New

Machine Type: Granulator

Video outgoing-inspection: Provided

Machinery Test Report: Provided

Marketing Type: New Product 2023

Warranty of core components: 1 Year

Core Components: PLC, Engine, Bearing, Gearbox, Motor, Gear

Brand Name: Reascend

Voltage: Customized

Dimension(L*W*H): Depends on capacity

Warranty: 1 Year

Key Selling Points: High Productivity

Applicable Industries: Manufacturing Plant, Farms, Energy & Mining

Showroom Location: Viet Nam, Indonesia, India, Thailand, South Korea, UAE, South Africa, Nigeria, Uzbekistan, Malaysia

Application: Fertilizer Pellet Making Machine

Usage: Producing phosphate

Material: State Standard Carbon Steel

Capacity: 10000-300000T/Y

Working method: Agglomerate

Installation: Professional installation team

Automatic grade: Fully Automatic

After-sales Service Provided: Field installation, commissioning and training

Product Description

Phosphorus is an important chemical raw material and an essential element for the growth of crops. Industrial phosphorus must be extracted from phosphate rock in large quantities to produce yellow phosphorus, red phosphorus, phosphoric acid, phosphate fertilizer, and phosphate. After phosphate rock is extracted, it can be used to produce phosphate rock powder, or use phosphate rock powder to produce compound fertilizers, or for the production of other fertilizers.

We can supply powder phosphate ore machines and granules machines for our clients.

The machines used for producing phosphate ore powder:

1.Jaw Crusher

This series of jaw crushers have the characteristics of large crushing ratio, uniform product size, simple structure, reliable work, simple maintenance, and economical operating costs. Jaw crushers are widely used in mining, building materials, chemical, metallurgical and other industries. They can perform coarse and medium crushing operations on various ores, rocks and other materials with a compressive strength of not more than 320MPa. They are the preferred equipment for crushing ore materials.

The working part of the jaw crusher is two jaws, one is a fixed jaw (fixed jaw), which is vertically (or slightly inclined at the upper end) fixed on the front wall of the machine body, and the other is a movable jaw (moving jaw). Inclined to form a crushing cavity (working cavity) with a large upper and a lower jaw with the fixed jaw. The movable jaw plate makes periodic reciprocating motion against the fixed jaw plate, sometimes separating and sometimes approaching. When separated, the material enters the crushing cavity, and the finished product is discharged from the lower part; when it is close, the material installed between the two jaws is crushed by squeezing, bending and splitting.

2.Raymond mill

Raymond mills are widely used in barite, calcite, potash feldspar, talc, marble, limestone, dolomite, fluorite, lime, activated clay, activated carbon, bentonite, kaolin, cement, phosphate rock, gypsum, glass , Insulation materials and other non-flammable and explosive mineral, chemical, construction and other industries with Mohs hardness not greater than 9.3 and humidity below 6%. The particle size can be adjusted arbitrarily within the range of 80-325 mesh, and some materials can reach up to 600 mesh.

The structure of the machine is mainly composed of a host, an analyzer, a fan, a finished product cyclone separator, a fine powder cyclone separator and a wind pipe. Among them, the host is composed of a frame, an air inlet volute, a blade, a grinding roller, a grinding ring, and a cover.

The working principle of Raymond mill:

When working, the material to be crushed is fed into the machine from the feed hopper on the side of the machine casing, and the grinding roller device suspended on the plum blossom frame of the main machine revolves around the vertical axis and rotates itself at the same time. Due to the centrifugal force during rotation, The grinding roller swings outwards and is pressed tightly against the grinding ring, so that the shovel blade scoops up the material and sends it between the grinding roller and the grinding ring. The material is crushed due to the rolling and rolling of the grinding roller.

The machines used for producing granules phosphate :

According to specifications of various raw materials , the general machines included in granular process can be as following:

1.Granulating machine : disc granulator ,rotary granulator ,compact granulator or other granulation machines.

2. Drying machines: It is used for removing or reducing moisture inside the granules

3.Cooling machines : it is used for reducing the granules temperature and improveing the granules hardness.

4.Sieving machines: It is used for sieving fine powder ,qualified granules and oversize materials. the unqualified materials will be recycled and re-granulated.

5.Packing machine as the last machine.

Project show

Our equipments have exported to South Africa,India,Korea,India,Saudi Arabia,Indonesia, Malaysia, Loas, Vietnam,Dominician republic,Mongolia,Spain and other countries.

Delivery site of NPK fertilizer making equipments to Indonesia client

The installation site of NPK compound fertilizer making equipments

The installation site of annual capacity 30,000 tons NPK fertilizer project in Vietnam

Loading equipments to our clients

Our fertilizer projects in China and other countries

NPK and organic fertilizer project in Africa

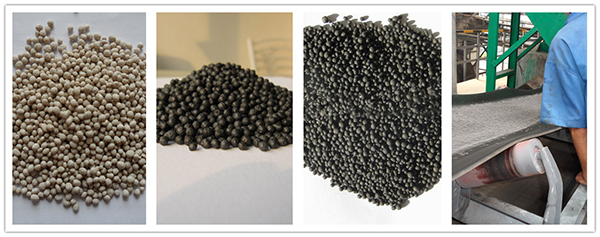

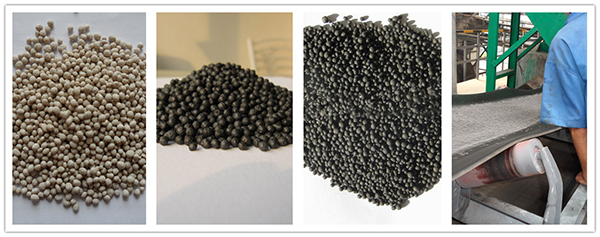

Final product produced by our machines:

Similar products:

1.NPK fertilizer production line

2.Organic fertilizer production line

3.Rotary dryer